Building Systems from Front to Back

Northfield Automation Systems knows the importance of considering a manufacturing effort from front to back and of fully understanding the end goals before a single piece of equipment is identified. We will get to know your company and process before we automate systems.

Taking any product from the laboratory through the pilot phase to a full-scale automated roll-to-roll processing or web handling system requires careful consideration of a number of variables.

- What are your options for raw materials and what are their characteristics?

- How will these materials react when various stresses are applied?

- What processes are involved at each stage and how do they interact?

- What are your expectations in terms of throughput and speed?

- What controls are necessary?

- What is the form factor of the product?

Our History in Roll-to-Roll Technology and Roll Processing Equipment

As a pioneer in the automation of roll-to-roll and web automation processing of flexible printed circuits decades ago, Northfield Automation Systems was one of the first companies to develop roll-to-roll and unwind rewind equipment that performed laser ablation on printed electronics. We were at the forefront of developing specifications for new and novel raw materials and then establishing a broad supplier base. Our low-inertia web handling rollers technology has become an industry standard, and our dancer system is without match.

The Innovative Impact of Web Automation and Roll-to-Roll Processing

The benefits of roll-to-roll processing are immense. By using roll-to-roll, web handling or web automation, there are more cost savings, better efficiency and stronger precision control – from incoming raw materials to the finished product. Through these automation systems and unwind rewind applications, Northfield Automation Systems is making an environmental impact by providing clean energy practices and energy-efficient roll-to-roll equipment, web automation equipment, and products. Web handling rollers, roll-to-roll processing and web automation make an innovative impact on any sheet transformation job.

Common applications for roll-to-roll processing in manufacturing include the following.

Flexible Electronic Devices

Whether you are using a standard substrate or a controlled number of substrates to create your flexible electronic device, roll-to-roll is the recommended manufacturing solution. By using a laminate or foil in a roll format, various sequence steps to create the product can be implemented. This may include cleaning the roll of material, creating vias, metallizing or plating, imaging (laser, photolith, print), or developing, etching, stripping, encapsulating or printing an insulating layer.

Each process step can be run via panel operation or roll-to-roll, and most can even be designed to run using either method – without needing to dedicate to only one. Converting with a web-to-panel machine allows the substrate to run through roll-to-roll where the process step has not been converted yet or panels are preferred to operate with. Such a machine allows for transition down the process flow with controlled conversion to roll-to-roll further through the manufacturing process. This tool can be used after for a final panelization process with additional options of inspection, test, serialization and sort.

Flexible Photovoltaics

Due to the precision required for flexible photovoltaic substrates, roll-to-roll manufacturing provides you with the controlled processing you need, along with higher throughput and reduced cost in manufacturing. The manufacturing of flexible photovoltaics, such as solar cells, can be completed using roll-to-roll printing and coating processes that are already widely used.

Fuel Cell and Energy Storage

Whether it is one material or a composite of multiple materials that are combined to make your fuel cell or energy storage product, this can be done in a roll-to-roll solution. This is because after manipulating the material substrate to the proper requirements in roll-to-roll, the downstream processing can be performed with a controlled speed, tension and alignment to form a buildup of your product within a complete roll of material that can be excised, inspected, tested, marked, sorted and stacked for final packaging.

Membranes

A roll-to-roll process is often the only viable way to produce products at high volumes and at manageable costs, including applications for membranes. Materials used in this type of manufacturing often require a closed, highly controlled environment and extremely sensitive handling. Tension and alignment are critical process parameters for these thin and often sensitive substrates.

Metal Foil and Sheet Manufacturing

Roll-to-roll processing allows you to maintain the integrity of the product without handling damage for a complete roll – especially important for foil and sheet manufacturing. High efficiency and greater continuous process control are possible with roll-to-roll, resulting in less material required, allowing you to produce more for less.

Products for the Medical Industry

Roll-to-roll provides a cutting edge to complete even the most complex products, including those in the medical industry. As medical devices get smaller, so do their components, making roll-to-roll perfect for medical device manufacturing.

Thin-Film Batteries

Not only can roll-to-roll processing help you maintain tight tolerances with thin-film battery base materials, it provides a more economical and environmentally friendly approach to manufacturing. Due to the high efficiency and precision control of roll-to-roll, less material is required, letting you produce product more efficiently. As electronics get smaller, so do their components, making roll-to-roll an effective solution for thin-film battery manufacturing.

Your Roll-to-Roll Project

At Northfield Automation Systems, roll-to-roll processing, web handling and automation, automation equipment, and roll handling equipment are in our very DNA. Let us bring our expertise in web handling and unwind rewind equipment to bear for you and your product.

Roll-to-Roll Test and Vision Inspection

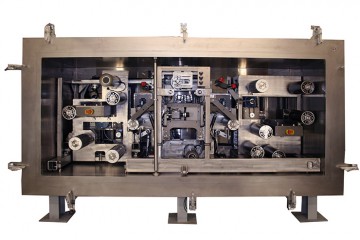

Roll-to-Roll Test and Vision Inspection Roll-to-Roll Vacuum Web Laminator

Roll-to-Roll Vacuum Web Laminator Roll-to-Roll Punch Press with Vision Inspection and Microclean

Roll-to-Roll Punch Press with Vision Inspection and Microclean Roll-to-Roll Modular Multi-Feature Laminator and Slitter

Roll-to-Roll Modular Multi-Feature Laminator and Slitter