Specifications

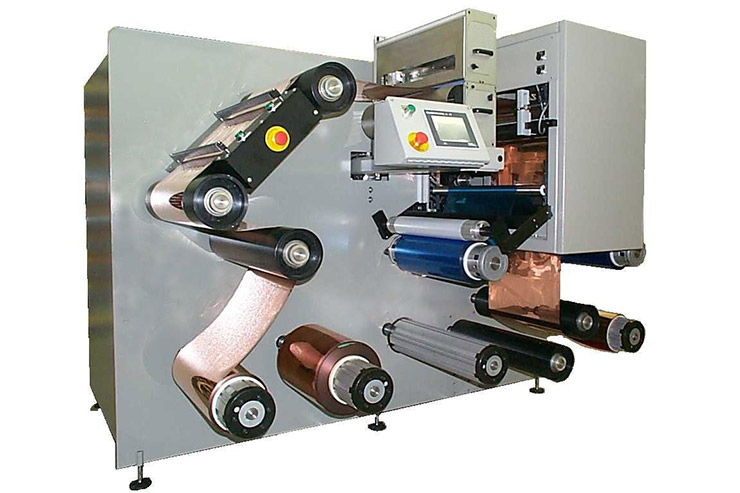

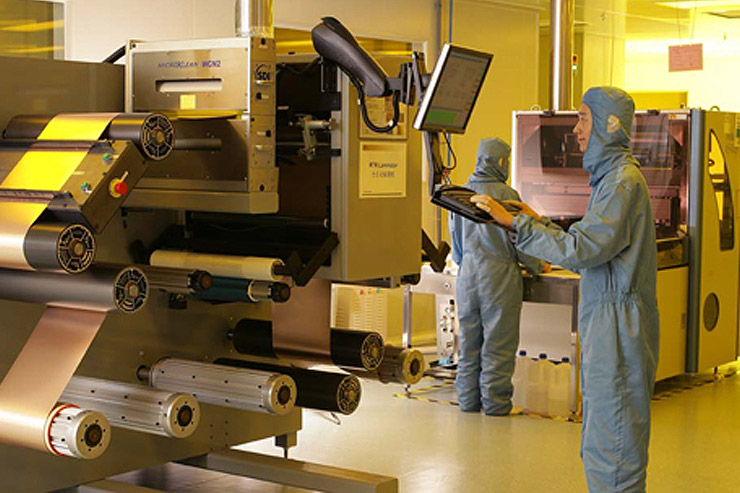

The Vertical laminator packs a large number of features into a compact footprint: Precise control of process speed and temperature combined with tight tolerance rollers provide utmost lamination quality.

The modular design allows customization to your specific applications. All options can be field installed, providing flexibility in the initial specifications. The base is designed to provide lift cart access for ergonomic loading of heavy rolls and the rollers are cantilevered for easy threading.

The unwind/rewind pair are PLC controlled with a touch screen user interface. Contact us today to learn more.

| Performance Features » | |

|---|---|

| Web width | 6-24 inches |

| Edge guidance | 0.004 inch accuracy |

| Feed rate | 0-15 FPM continuous |

| Material roll diameter | Up to 16 inches |

| Material spool direction | Both CW and CCW |

| Splice station | For accurate splicing |

| Web tension | 4-40 lbf |

| Pressure regulation | 2-80 psi +/- 0.1% |

| Material shaft T.I.R | Less than 0.005 inches |

| Idler diameter | 6 inches |

| Idler T.I.R. | Less than 0.002 inches |

| Roller alignment | Level and parallel to 0.003 in. |

| Standard Features » | |

| Material construction | Stainless or powdercoat steel / anodized aluminum |

| Material core | Pneumatic – touch screen activated |

| Material drive | Safety clutch included |

| Controls | PLC controlled |

| Electrical panel | UL certified |

| Options » | |

| Pre-heat roller | Pre-heat material prior to lamination for better bond. |

| Splice station | Allows precise splicing of material |

| Viton coated lamination controllers | Significantly increases lamination roller life. |

| Dual material shaft and accumulation | For uninterrupted material processing during roll change. |

| Tension control | Closed loop/remote set |

| Inline inspection | Verification of process parameters prior to upstream processing. |

| Process data collection | Many SCADA packages available |

| Web cleaner | Tacky roll, ultrasonic, etc. |

| Laser alignment | Entire process line aligned to 0.003 in. |

| Dimensions and Power » | |

| Machine size (LxDxH): | 82 x 82 x 80 in. (1219 x 1855 x 2007 mm) |

| System weight | 2000 lb. |

| Electrical | 120/240 single phase 60/50 Hz (specifiy) |

| Air | 80 psi |

| Exhaust | 350 CFM |