Overview

As technological devices become smaller, thinner and lighter, manufacturers of printed electronics need to ensure they have improved capabilities to achieve the tighter tolerances and handle the more sensitive materials required to create components for these increasingly smaller devices.

A Partner for the Future of Electronics

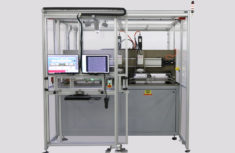

In the printed electronics world, Northfield Automation Systems understands the importance of handling materials as minimally and controllably as possible and detecting even the smallest of defects. We also understand that creating smaller electronics does not mean having to sacrifice speed, capacity, and yield.

We excel in fully automated printed electronics solutions (roll-to-roll, robotics, and panel handling) and its derivatives, including:

- Display (deformable electronics)

- Touch sensor

- Virtual Reality technology

- FPC (flexible printed circuits)

- PCB (printed circuit boards)

- Medical devices

- Flexible battery

- Solar cells

Our solutions offer high-volume testing (stand-alone or in-line), and closed-loop process control designed to improve the quality and increase yield. Our vision inspection systems detect defects unseen to the human eye, and our roll-to-roll systems require minimal handling, allowing companies to reduce the damage that occurs when extremely thin materials are handled.

PROCESS

No matter the equipment automation project at hand, we deliver solutions that expand your printed electronics capabilities and empower and streamline your business operations with automated equipment.

Through every step of our automation projects, we ensure that our equipment is designed to improve performance and increase efficiency and that our custom automation machines are tailored specifically to your project needs.

One Stop Shop

Greater Quality

Cost Savings

Northfield Automation Systems was critical to completing our project. Their tools allowed us to implement roll-to-roll handling. Without them, it wouldn't have been possible.

Roll-to-Roll Test and Vision Inspection

Roll-to-Roll Test and Vision Inspection Roll-to-Roll Punch Press with Vision Inspection and Microclean

Roll-to-Roll Punch Press with Vision Inspection and Microclean Custom Vertical and Horizontal Panel Handler

Custom Vertical and Horizontal Panel Handler Turnkey Panel Automation Process

Turnkey Panel Automation Process