Specifications

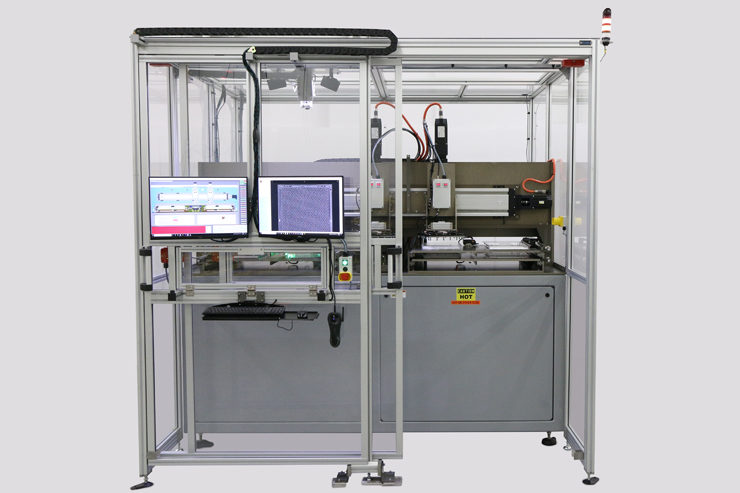

This stand-alone, complete process station turnkey panel automation solution includes a HEPA enclosure with full safety interlocks and lighting. The operator is able to access safety-switched drawers that are allowed to open when a tray of panels is completed. This design allows for multiple trays to be loaded as well as continuous operation, even when a tray is fully completed. The operator can remove and load trays safely while other trays are in operation.

ADDITIONAL FEATURES

This station includes:

- an area camera for product identification

- barcode reading for serialization and part identification

- custom gantry end effectors for optimal panel handling

- custom vacuum stage for precision panel control and placement reliability

- line scan cameras

- laser marking station for full panel scanning and marking

These features require an overall program that synchronizes all of steps and functions to perform smoothly and efficiently throughout for the fastest cycle time with optimal reliable performance.

USING MONITORS TO ENSURE QUALITY

This process utilizes two monitors. One displays all motion and state of each process feature, along with the product specific process parameters with setpoints. The other monitor displays quality fails with images and mapping for characterization and locations for repeats or damage areas.