Experience Pays Off

Northfield Automation Systems meets customer needs by delivering finely tuned control of the roll lamination process. Our staff’s 75+ years of experience in high-volume flexible circuit and PCB fabrication has been used to develop accurate, precise, durable and ergonomic laminators.

Easy Maintenance Saves Time

Our machines handle thin materials and are designed for fast change-over and easy maintenance. Off-the-shelf laminators won’t give you nearly the control over the heat profile and pressure across the roll that Northfield Automation Systems can provide.

On a standard laminator, a damaged roller could take an operation down for an entire shift. When Northfield Automation Systems lamination systems are in place, if a roller is damaged, a single operator can change it and have it running again within an hour. That’s a huge impact for productivity and profitability.

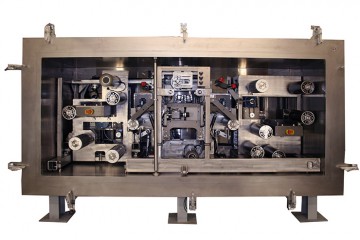

Roll-to-Roll Vacuum Web Laminator

Roll-to-Roll Vacuum Web Laminator Hybrid Robotic Wafer Laminator/Sheeter/Stacker

Hybrid Robotic Wafer Laminator/Sheeter/Stacker Roll-to-Roll Modular Multi-Feature Laminator and Slitter

Roll-to-Roll Modular Multi-Feature Laminator and Slitter