Ensuring Product Quality

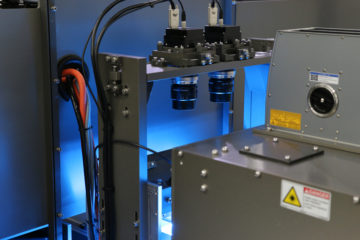

Northfield Automation Systems creates world-class visual in-line inspection systems that balance fine-level defect resolution with rapid roll-to-roll and web automation processes. Using high-end commercial lenses and lighting, we internally develop custom software to resolve the images. We create vision inspection systems for the following applications:

- Defect detection

- Quality inspection

- Verification tool

- Statistical analyzer

- High-speed counter

- Color analyzer

The great value in integrating a visual inspection system is the ability to ensure product quality and identify problems. When an inspection system is paired with a characterization functionality – say, a laser-marking or barcoding system – you have the ability to mark or track the product for future action.

Multi-step Detection

Beyond simple blob detection, our advanced vision inspection systems have the ability to conduct multi-factor, multi-step feature detection.

The ability to handle a complex series of inspections – all while allowing for the efficient forward movement of the web itself – comes from the right combination of hardware and software, both of which NAS designs and configures.

In some instances our systems will inspect multiple points of interest on a web, record and examine the data, and then overlap and stitch the image, providing both a macro and micro record of the inspection.

Our optical inspection equipment can improve outgoing quality by finding defects that ordinary visual inspection would normally miss, and give valuable process feedback for continuous improvement efforts.

In-Line Multi-Purpose Line-Scan Vision System

In-Line Multi-Purpose Line-Scan Vision System Roll-to-Roll Test and Vision Inspection

Roll-to-Roll Test and Vision Inspection Robotic Measure, Sort and Vision Inspection

Robotic Measure, Sort and Vision Inspection