Specifications

For this project, the customer order called for a minimum 200-Ton Punch and DeBurr Station using a punch press and hard tooled die set to punch continuous, horizontal webs with a matrix of holes and subsequently move through a deburring process to remove any burrs left from the punching process. The equipment performed in a step and repeat motion. The equipment setup was Dry-In-Dry-Out. It operated in a high-throughput 24×7 manufacturing environment. Web material is predominantly Al foil with a CIGS coating, but other web materials can be used in the tool for experimental purposes.

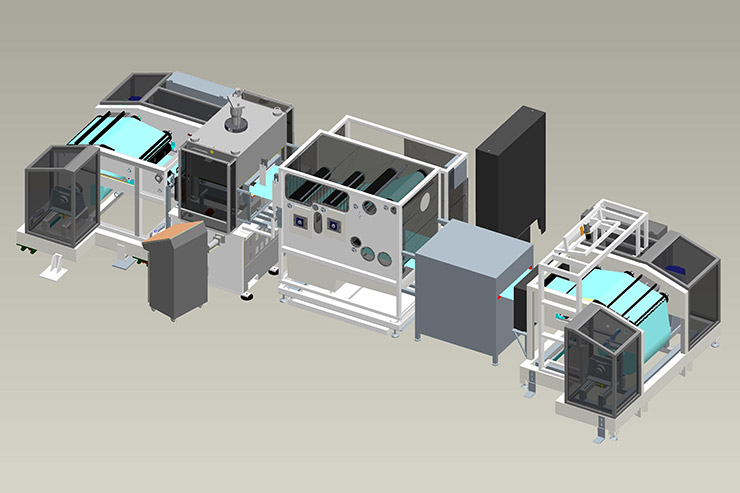

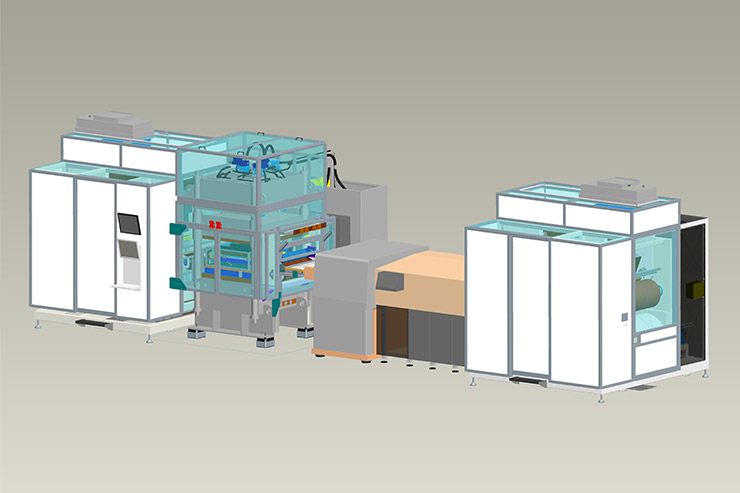

Equipment Overview

The equipment consists of these subdivisions:

Unwind

- Material Core: Unwinds product in either CW or CCW direction

- Interleaf / Leader Shaft: Pays out leader or takes-up interleaf

- Unwind Splice Station: Splices un-punched material or leader web

Punch Press

- Holds DIE set to punch VIA’s into material web

- DIE and web lubricant (ex. isopropyl alcohol) delivery

- Vision registration for punch-to-punch alignment (+/– 0.001″) — down and cross web.

- Inspection for missing punches and burr heights

Deburring Station

- Deburrs backside of web with flap brushes

- Rinses with DI water

- Dries Web

Rewind

- Material Core: Rewinds product in either CW or CCW direction

- Interleaf / Leader Shaft: Takes-up leader or pays out interleaf

- Rewind Splice Station: Splices punched material web

- Cleans both sides of the web.

Web Tension Systems: Creates constant web tension. The tool will have three (3) tension zones: unwind, rewind and process.

The 200-Ton Punch and Deburr station is a fully automatic machine, controlled by a programmable logic controller (PLC) or computer. The machine controls critical parameters, monitors the process, displays the current status and alerts the operator if errors occur. Contact us today to learn more.