The Issue

The Issue

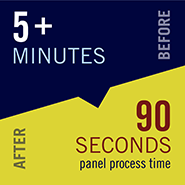

As the manufacturer was preparing for a new product launch they needed to upgrade their process requirement to accommodate the tighter tolerances required with specific operations on each part within a panel. The density of parts on each panel were requiring multiple minutes to process.

The Solution

Northfield Automation Systems developed a custom solution that has enabled finer feature marking and tighter tolerances that could not be achieved on their existing equipment.

The Results

The new process solution increased throughput and gave the manufacturer the capability to meet the product’s next-generation requirements. Process time was reduced from over five minutes per panel on average to just under 90 seconds.