… Increased Accuracy and Cost Savings

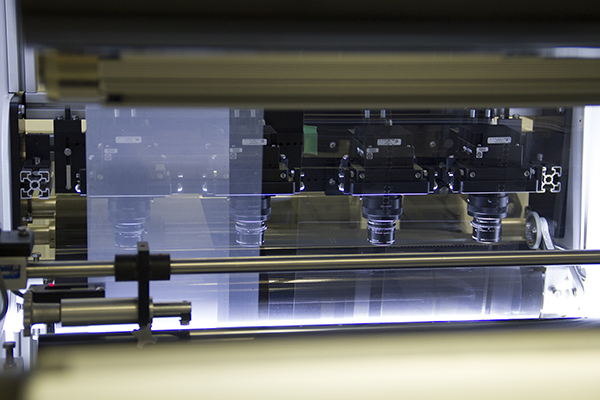

It’s our system, but it’s your gain. At Northfield Automation Systems, our visual in-line inspection systems balance fine-level defect resolution with rapid roll-to-roll processes. Using high-end commercial lenses and lighting, we internally develop custom software to resolve the images. These world-class systems provide a number of beneficial impacts for manufacturers.

Better Quality. Fewer Errors.

When manufacturers integrate a visual inspection system into their processes, they start to see the benefits immediately.

- Immediate process control feedback

- Consistency with in-line automation

- Increased cost savings

- Quality control near the source

- Quickly identify problems

- Identify results from continuous improvement efforts

Vision inspection allows manufacturers to uphold their strong reputations by ensuring quality products time and again.

The Right Combination

The team at Northfield Automation Systems brings decades of experience and skilled expertise to your projects. Customized solutions mean the right combination of hardware and software, designed and configured right here, in-house at NAS.

Contact one of our engineers today to learn more about vision inspection systems and how they can positively impact your bottom line.