Specifications

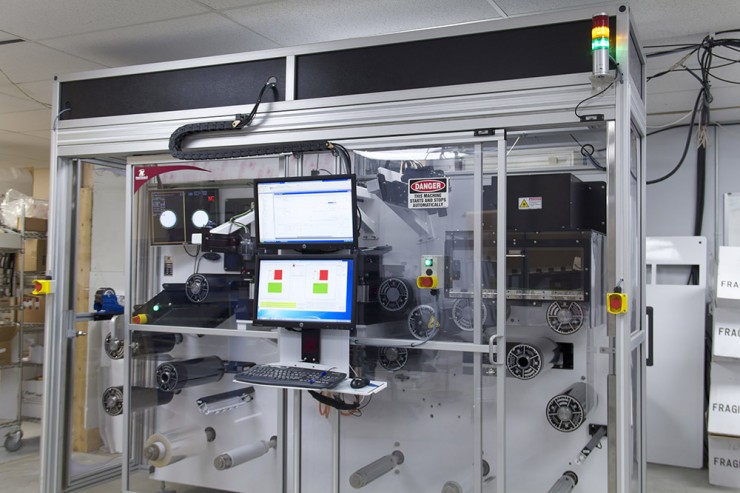

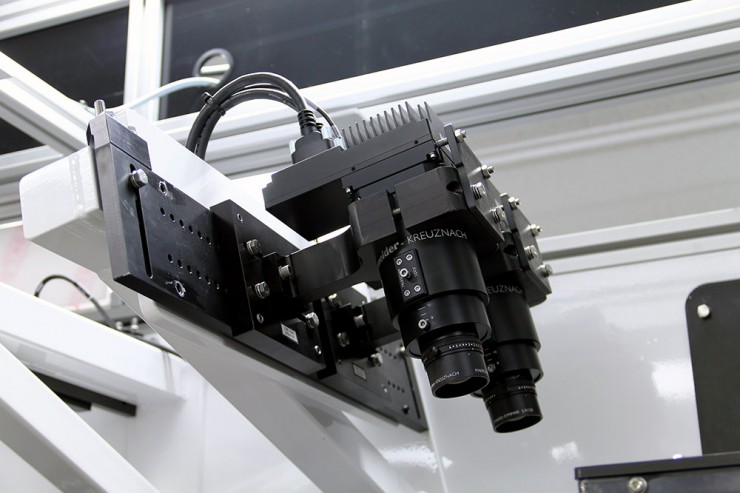

For high-end vision inspection, NAS utilizes multiple 16K line scan cameras to continuously inspect the whole web (while maintaining a high resolution) to find all defects of concern for the product. For example, NAS has completed projects seeking to identify 25 micron defects on a 300mm wide web with 100% web coverage.

Alternative configurations utilize an “audit” strategy where full coverage is not required. For continuous high resolution inspection, our systems have the ability to save images and log every inspection (primarily for initial setup and troubleshooting). In production use, the system can be configured to only save cropped images to show actual defects found and the data log detailing the exact location and nature of the defect.

Offline analysis tools allow tuning and control of vision parameters to allow continuous optimization of the inspection. For more information, contact us today.