Specifications

Process

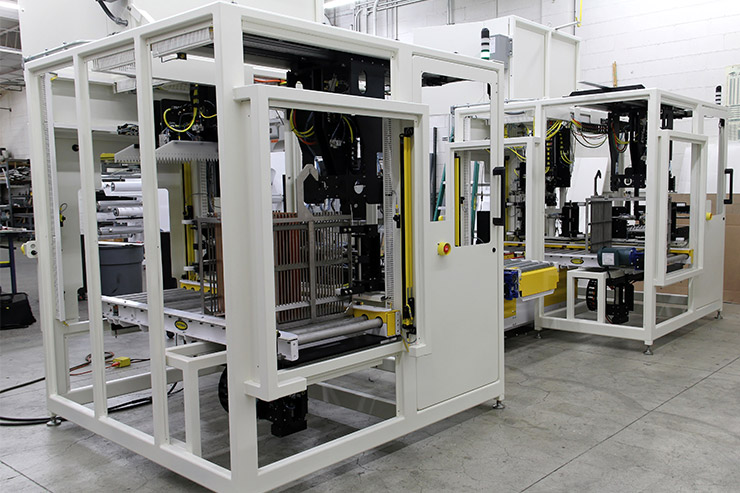

- Basket is manually loaded onto load/unload system conveyor.

- Basket moves from home position to load position #1.

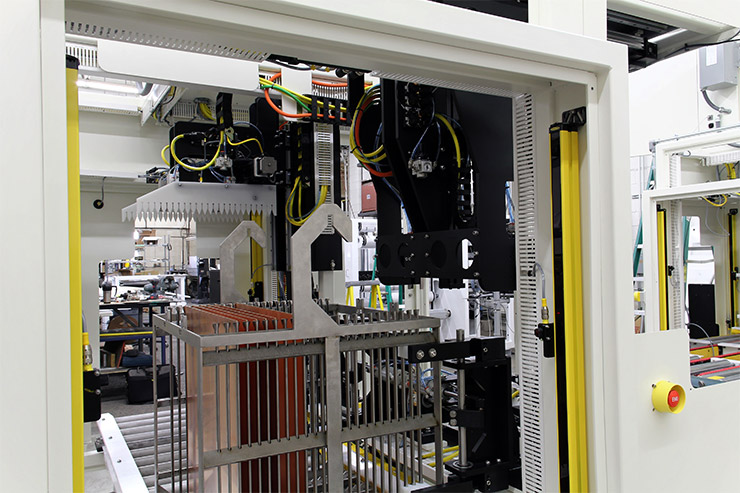

- Flat panel alignment cap removed to allow basket to accept panel.

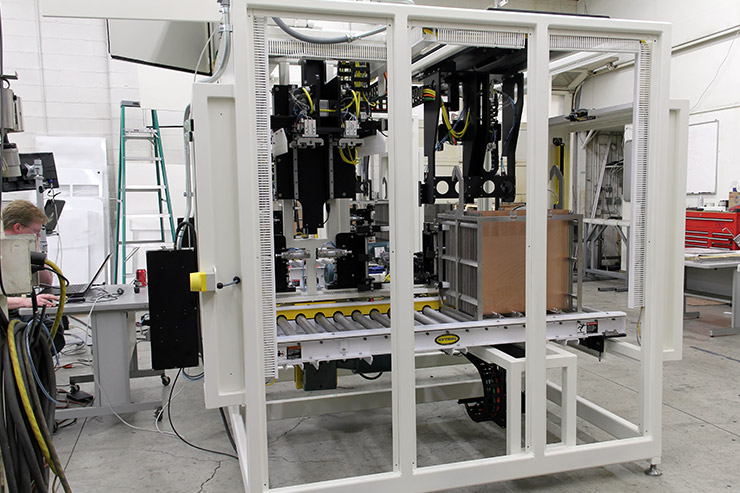

- Load/unload system: customer-supplied indexing conveyor receives a flat panel within +/-3.0mm from horizontal position using lead-in feature.

- Flat panel travels (index’s) on customer-supplied conveyor to staging area.

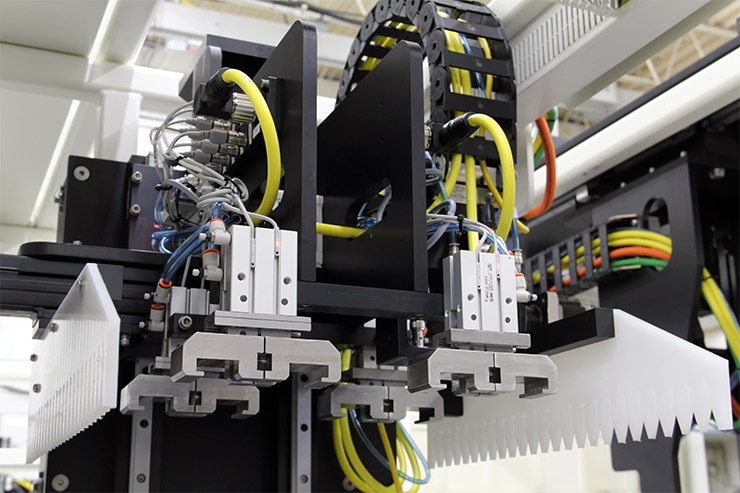

- Vacuum paddle with lead-in feature receives flat panel from staging area. (Vacuum paddle fastens to customer-supplied conveyor).

- Vacuum paddle holds flat panel in 10mm exclusion zone and then rotates flat panel to vertical position. Vacuum paddle releases flat panel onto lift vane below basket; lift vane lowers flat panel into basket.

- When basket is full, it travels back to home position on conveyor; flat panel alignment caps are reinstalled and full basket is ready for processing. (The movement and rotation of panel into basket and the movement of full basket are to be a smooth motion as not to allow panel to warp more than 6.0mm)

- At the equipment output the panel must be positioned so that panel centerline is within +/-1.0mm from nominal.

- Reverse steps above for flat panel unload.

| Performance of load/unload system | |

|---|---|

| Availability | Supplier dependent uptime is 90%. Per definitions in SEMI E10. |

| Scheduled down time | Less than 12 hours per week (Including PM + setup time). |

| Run Rate | 86 Panels per hour |

| Max Panel Warpage | 6.0mm (When panel is placed on a flat horizontal surface, warpage is the largest distance between surface and panel. Gravity may also cause sag in panel that equipment must accommodate. |

For more information, contact us today.